- Plywoods[10]

- Formwork[4]

- Mouldings[2]

- Other Furniture Parts[2]

- Veneers[1]

- Contact Person : Mr. Jiang Mr

- Company Name : Linyi Ruifeng Wood Co., Ltd.

- Tel : 86-539-8622225

- Fax : 86-539-8636977

- Address : Shandong,Linyi,Beidianzi Village, Zaogoutou Town, Lanshan District, Linyi City, Shandong Province. China

- Country/Region : China

- Zip : 276038

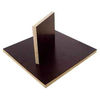

Formwork Plywood

Formwork Plywood

Our Phenolic Film-faced plywood are available with smooth or mesh (reduced-slip) finishes. The phenolic films are impervious to water, the smooth variant being ideal for concrete formwork where the form is to be repeatedly reused. Paper overlay plywood also appear in the extension range. Substrates include Tropical Hardwood, Birch and poplar Plywood’s.

OVERLAY | A smooth, phenolic film is hot-pressed onto the panel surface. The film consists of base papers impregnated with phenolic resin. A film with a basis weight of 120g/m2 is normally used. Film basis weights of 170g/m2 and 220g/m2. Multilayer overlays are also available by order. | ||||||||||||||||||||||||||||||

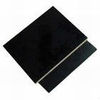

FILM-COLOR | Usually dark brown. Finland produce and black also available for order. | ||||||||||||||||||||||||||||||

EDGE SEALING | Panel edges are sealed against moisture absorption with acrylic paint. The edge color is normally dark brown, but it is also possible to order edge sealing tinted to match the overlay color. Even though edge sealing hinders the absorption of moisture into the panel, it does not eliminate it completely. | ||||||||||||||||||||||||||||||

FILM SURFACE PROPERTIES | The film surface is semi-glossy, smooth, hard and slippery. It withstands abrasion. Is moisture resistant and can tolerate commonly used chemicals as well as diluted acids and alkalis. The surface is a easy to clean with water and steam. Moisture absorption is minimum. The color of the film surface will change over the years due to UV rays in sunlight, and will fade slightly when used outdoors. | ||||||||||||||||||||||||||||||

BONDING CLASSES | Standard plywood panels are bonded with phenolic resin adhesive (WBP, BFU, AW, exterior), are resistant to weather and boiling water, and meet the following international bonding standards: BS 6566 part 8/type WBP. | ||||||||||||||||||||||||||||||

THICKNESS |

9.0mm-21.0mm

| ||||||||||||||||||||||||||||||

TOLERANCE | ±0.5mm | ||||||||||||||||||||||||||||||

SIZES | 1220 x 2440mm, 1250x 2500mm | ||||||||||||||||||||||||||||||

QUALITY CONTROL | External plywood quality control are conducted in accordance to ISO and CE certificate. | ||||||||||||||||||||||||||||||

PACKING | Standard export package: Inner with waterproof plastic bag, outside with 3mm plywood and carton, then fastened with 3'x6' sheet iron and packed with pallet |

Formwork Plywood